Phylogenetically, L. delbrueckii subsp. bulgaricus is closely related (<10% sequence divergence) to L. amylovorus, L. acidophilus, L. helveticus, L. acetotolerans, L. gasseri, and L. amylophilus (Schleifer and Ludwig, 1995). The GC ratio of L. delbrueckii subsp. bulgaricus (49-51%) is somewhat higher than that found among other species (34 to 46%) within this phylogenetic tree (Hammes and Vogel, 1995). The genome size of L. delbrueckii subsp. bulgaricus has been determined to be 2.3 Mbp by pulse-field gel electrophoresis (Leong-Morgenthaler, 1990). Very few chromosomal genes (<15) have been sequenced from L. delbrueckii subsp. bulgaricus, however the complete sequence of a small cryptic plasmid and the partial sequence of a bacteriophage are known. Gene transfer systems for L. delbrueckii subsp. bulgaricus have recently been described. These include two conjugation-based gene transfer systems (Rantsiou et al., 1999; Thompson et al., 1999) and electroporation (Serror et al., 2002). L. delbrueckii subsp. bulgaricus is a component of “thermophillic” starter cultures used in the manufacture of a number of fermented dairy products (Hassan and Frank, 2001). These cultures have an optimum growth temperature of approximately 42oC and contain Streptococcus thermophilus with L. delbrueckii subsp. bulgaricus and/or L. helveticus. These cultures are utilized in the yogurt, Swiss-type and Italian-type cheese varieties. There has been a significant increase in the past twenty years in the production of both Mozzarella cheese and yogurt in the United States. According to USDA statistics, in 1980, 688,000,000 pounds of Mozzarella cheese were produced in the U.S. (National Cheese Institute, 1998). By 1998, Mozzarella production had increased 325%, to more than 2,244,000,000 pounds, with an economic value of nearly $1 billion (National Cheese Institute, 1998). Yogurt production has seen a similar increase, from 570,000,000 pounds in 1980 to 1,371,000,000 pounds in 1997, a 240% increase. The wholesale value of yogurt in 1997 was over $1.1 billion (Milk Industry Foundation, 1998). Therefore, L. delbrueckii subsp. bulgaricus is utilized in the manufacture of products in the United States with a value of more than $2.1 billion. To have utility in the manufacture of fermented dairy products strains must be resistant to bacteriophage, have stable fermentation properties, and consistently produce products with acceptable flavor and texture attributes. A significant body of research is available concerning the proteolytic system of these organisms and limited information is available concerning a number of industrially relevant metabolic pathways (i.e. carbohydrate fermentation). Genomic sequence analysis of L. delbrueckii subsp. bulgaricus will allow researchers to fill the significant gaps present in our understanding of the physiology of this organism by providing a comprehensive view of the enzymes and metabolic pathways potentially involved in industrially relevant phenotypes. This knowledge will allow researchers to develop more effective strategies to enhance the utility of these organisms in the manufacture of yogurt, Swiss-type and Italian-type cheese varieties. References:

|

||

|

||

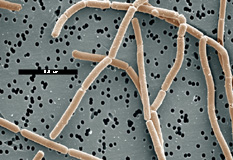

Lactobacillus delbrueckii subsp. bulgaricus ATCC BAA-365